We join the dots in Show Two: Design and Designing in Turbulent Times by exploring two projects with alternative perspectives on automation

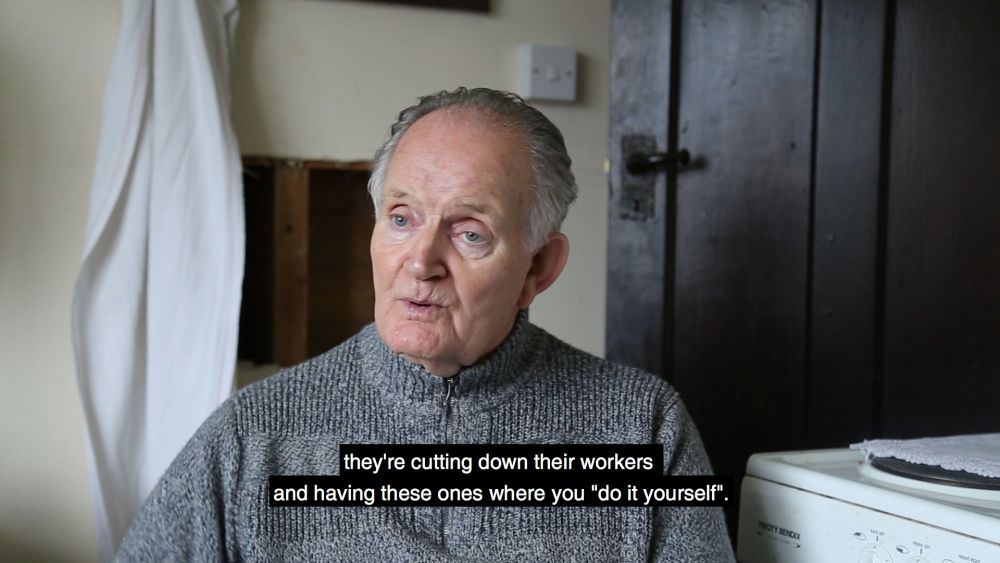

Interested in how automation has impacted communities around the UK, Maël Henaff, MA Material Futures, headed to Jaywick on the Essex coast. The town had been visited by UN representatives in 2018 investigating poverty, the roll-out of Universal credit and the effects of automation on local industry.

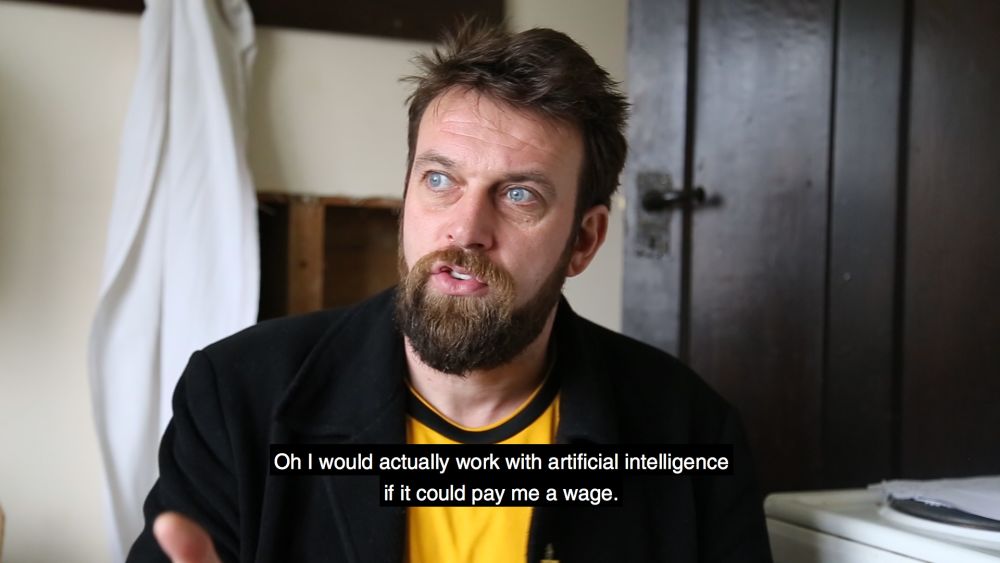

Interviewing members of the community, Henaff heard how jobs were being lost to new technologies, from car manufacturing to retail. “I thought that we have to do something,” he says, “It’s not about being able to solve such a massive problem, but I wanted to give more tools to the community. Artificial intelligence and machine learning are just tools and they can be used to benefit private industry or they can be used for social good. That was the start of the project.”

Gallery

Henaff made a documentary, interviewing people from different generations about their fears around emerging technologies and its impact on the town. Then through workshops and co-design, he worked with the group to devise ways to create income for the community. Together, they designed and built machines that float on the coast and use tidal energy to mine cryptocurrencies. Each one creates a small profit – 2p every 30 minutes – but as the group built more machines their income grew. The devices create a supplementary income but also, Henaff hopes, the process replaced negative and passive perspectives on new technologies with positive, active ones.

While the project came about because new technologies have reduced opportunities for work in Jaywick, Henaff’s initial curiosity was piqued by the provocation that a fully-automated future will not simply revolutionise work but remove it altogether.

“We define ourselves by the jobs we have. But do we have the right not to work?” Maël Henaff

Automation and the end of work appears in Graysha Audren's BA Textile Design project as she harnesses cutting-edge technology for Seamless: Woven Workwear for an Automated Future. She looks to the year 2100 when “manual labour is a thing of the past with universal basic income providing a new generation of leisure”.

Gallery

Taking inspiration from the UK’s only 3D weaving machine which can weave 20 layers at a time Audren has designed a series of garments for a future world. Her resulting collection is nostalgia workwear created on 3D weaving machines, each one bespoke to fit the wearer.

Her interest in technological innovation stems from the problem of waste in the current fashion system. In garment production 6-25% of the fabric is wasted in off-cuts and 73% of all textiles produced end up in landfills or incinerated. Audren's approach is to reform the system with the advent of seamless woven garments.

“So many efforts have been put into making fast fashion immoral but we continue to buy it. This moral righteousness doesn’t work. The only thing that will work is persuading people with money and efficiency; if you can provide a sustainable item that’s good for the company that manufactures it in terms of profit as well as it being sustainable. That’s the win-win.” Graysha Audren

Maël Henaff was nominated for the MullenLowe NOVA Awards and Graysha Audren won a commendation in the LVMH Green Trail. Both projects were exhibited in Show Two: Design at Central Saint Martins, 19-23 June and can be seen in Designing in Turbulent Times at the Lethaby Gallery, 14 September – 27 October.