Our students and alumni

-

Aly Tobin

BA (Hons) Cordwainers Footwear: Product Design and Innovation alum

-

Melanie Dagher

MA Fashion Media Production alum

-

Natalie Grogan

MA Fashion Media Production alum

-

James Long

BA (Hons) Fashion Design Technology: Menswear alum

Our teaching staff

-

Lilia Yip

Lilia Yip

Lecturer, BA (Hons) Fashion Design and Development

-

Minal Malik

Minal Malik

Lecturer, BA (Hons) Fashion Marketing

-

Staff - Diogo Baltazar

Diogo Baltazar

Course Leader for MSc Cosmetic Science

-

Ayshen Ali

Lecturer, Fashion Management

Our research staff

-

Amy De La Haye

Professor of Dress History and Curatorship

-

Reina Lewis

Artscom Centenary Professor of Cultural Studies

-

Shahidha Bari

Professor in Fashion Cultures and Histories

-

Graeme Evans

Professor in Creative and Cultural Economy

Stories

-

Nicoletta Akabuogu Meet Nicoletta Akabuogu, BA (Hons) Fashion Pattern Cutting graduate

Recent graduate, Nicoletta tells us about her experience at LCF and her journey to Africa Fashion Week.

-

Photo: Eugenie Flochel Somers Gallery Exhibition by Louise Thornton

MA Fashion Curation Alumna Louise Thornton writes about her work on an community project exhibition at Somers Gallery

-

Work by bespoke tailor Caroline Andrew Life of Alumni: breaking into the world of bespoke tailoring with Caroline Andrew

BA Bespoke Tailoring alumna Caroline Andrew shares an insight into her journey as a tailor working in London.

-

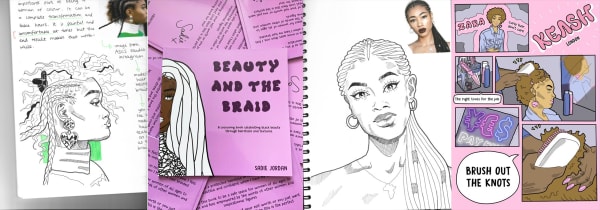

Student Spotlight: Sadie Jordan from BA (Hons) Fashion Imaging and Illustration talks about representation and creative wellbeing

Recent LCF alumna Sadie Jordan discusses why representation in fashion imaging matters, and what inspired the illustrations in her new colouring book 'Beauty and the Braid'.